Robust and reliable, the latest generation of Peltier cooling modules can cool an IC, and a variety of other components like LEDs and laser diodes, to a target temperature, while also preserving stability where load changes rapidly. This makes them a persuasive addition to any designer’s thermal management toolbox.

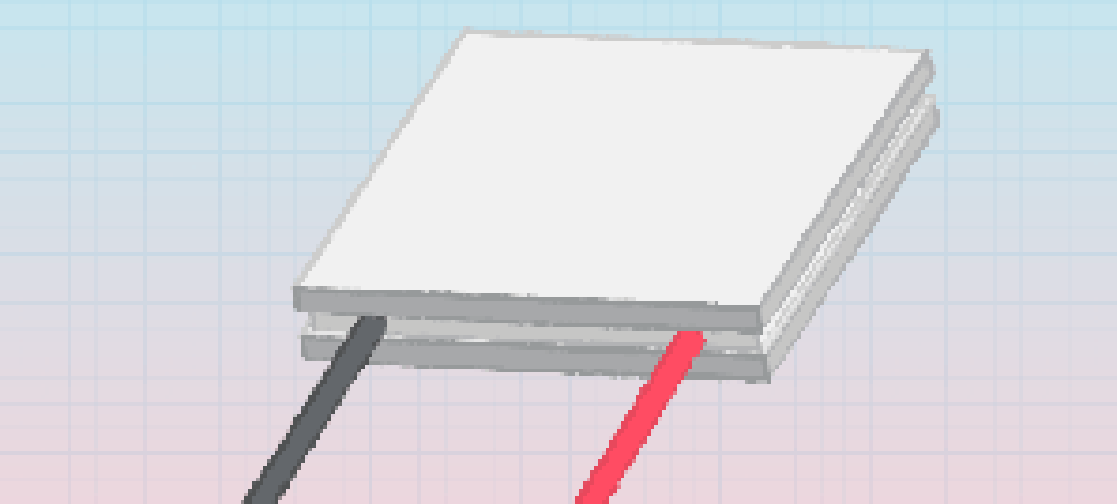

Peltier modules are active devices, powered via a current source to maintain the temperature difference between their hot and cold sides. In addition, they can cool down components to below their ambient temperature, providing greater scope to enhance reliability and boost performance of cooled components.

Before incorporating a Peltier module, a designer needs to know its cold-side temperature, as it corresponds to the desired temperature of the device being cooled, together with the maximum temperature difference between its hot and cold plates. Presented graphically in the datasheet, the module’s electrical and thermal characteristics can be used to calculate the voltage compliance and operating current required of the current source. Design success hinges on a basic familiarity with the way the modules function, as well as good, solid characterization data.

In this CUI Insights blog, Bruce Rose, Principal Applications Engineer at CUI, has delved into the topic of ‘How to Select a Peltier Module’. Rose’s blog post explains the operating principles of Peltier modules and describes a typical mechanical assembly, while demonstrating how to combine application cooling requirements and datasheet performance curves to select the most appropriate module for a given design.