The Worshipful Company of Engineers’ (WCE) recently paid a visit to the Department of Engineering.

We were privileged to be visited by The Worshipful Company of Engineers (the “Company”) on Friday 16 September as part of their Annual “Out of Town” Weekend. This Out of Town Event was organised by the Master of the Company. The current holder of that title is Cambridge Engineering and Churchill Alumna, Audrey Canning MA CEng FIET FRSA MSaRS MIO. The Friday is always spent on a technical day for members of the Company. Cambridge was also an appropriate destination as the Company has previously supported Cambridge PhD students through its Leete Awards, for which the Department is very grateful. Through its charity, the Engineers Trust, the Company donates to a wide range of awards and prizes, primarily for younger engineers and apprentices.

The group visited the Institute of Manufacturing (IfM) for a morning of presentations and mini tours. They heard an introduction to the IfM from Professor Richard Prager, Head of Department at Engineering, explaining the wider multidisciplinary hub nature of the Department of which the IfM is a part. The introduction gave a flavour of the history of key innovations emanating from the IfM and the three core activities (Research, Education & Application/Consultancy) and examples of current projects with various commercial clients, partners and spin outs.

Dr Florian Urmetzer, and Professor Ronan Daly gave an overview of the structure of the undergraduate and master’s qualifications with their strong focus on industrial projects of practical relevance carried out at the sites of industrial partners. Professor Daly explained the IfM’s scientific methodology applied to technology scale-up, particularly for smaller spinout enterprises, with several recent examples of the approach in practice.

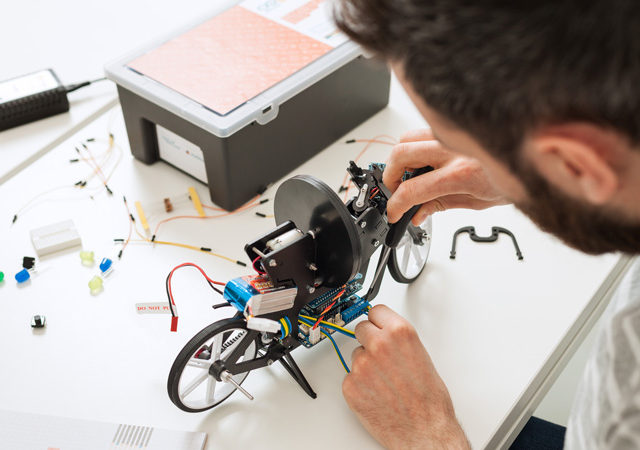

There was then a tour of the Robotics Lab and a visit to one of the undergraduate project rooms with various poster displays of recent projects.

The group walked down the road to the Material Science & Metallurgy Department where they heard firstly from Professor Howard Stone and Professor Nick Jones regarding the development/transformation of novel super alloys, controlling crystal structures in single crystal turbine blades and additive layer manufacturing.

This was then followed by Professor Chris Pickard and Dr Bartomeu Monserrat presenting their research utilising quantum mechanics and AI to streamline the development of new materials with specific targeted properties.

These presentations were followed by a tour of the Process Laboratories and Workshops. The labs and workshops are very impressive with an extensive range of furnaces, casting and metallurgical handling equipment and a complete suite of X-ray and electron microscopes including the brand new Spectra 300 Scanning Transmission Electron Microscope which was just reaching the end of its commissioning period and whose configuration and abilities make it the only one of its kind in the UK.

Update on the WCE Leete Award sponsored students

Returning to the Institute for Manufacturing the group heard about the research and subsequent careers of the four postgraduate researchers whose PhD research in manufacturing technology was sponsored by the Worshipful Company of Engineers’ – specifically the three year Leete Premium Award for manufacturing excellence.

Jon Parkins (2013-2016) – developed technology to improve production of 3-D printed hip implant components.

Professor Ronan Daly spoke about the award winners, noting that all had gone on to interesting careers and three of whom were still in touch with the Institute.

Bio-inspired robotics

In the afternoon the group met Professor Fumiya Iida, Professor of Robotics who moved to Cambridge in 2014 to set up the Bio-inspired Robotics Laboratory after gaining a degree in mechanical engineering in Tokyo University of Science and post doc work at ETH Zurich.

Professor Iida introduced the complexities of vegetable harvesting, a significant problem in the East of England where the total income from farming in 2019 was £885M. Given the shortage of labour for harvesting, it is becoming increasingly difficult to balance the economics of vegetable production.

He illustrated his talk with the example of ‘lettuce harvesting’ showing how human harvesters can detect individual lettuces, determine which are worth harvesting, hold them gently to avoid damage, then trim away the outside leaves in one swift ‘hack’ through the main stem. The end product is a perfectly prepared, clean, ‘supermarket ready’ specimen in around 15 seconds.

A robot replacement has many problems to overcome. Professor Iida noted that the problems are not new; he quoted Muravec (Harvard, 1988) ‘that whilst it is easy to make a robot which mimics an adult it is impossible to give them the self learning skills of a one year old child when it comes to perception and mobility’.

In the case of lettuce harvesting, first the robot must identify a specific ‘target vegetable’ amongst a chaotic pattern of intermingled leaves. Then it must determine which lettuces are ready for harvest, leaving others to grow further and rejecting those that have failed to form adequate ‘hearts’. Then it must ‘secure’ the lettuce with a grip that is sufficiently firm to allow a knife to be applied to the stem – but not so firm as to crush the lettuce itself, and finally it must determine where to make the ‘trimming hack’ to remove the tatty leaves, but leave the maximum amount of heart before transferring the lettuce to the trailer.

Professor Iida’s work focusses on the application of soft sensing technologies and adaptive stiffening for wearable devices, haptic interfaces and robotic systems. The mechanical properties of a sensor strongly affect its tactile sensing capabilities. By exploiting tactile filters, mechanical structures between the sensing unit and the environment, it is possible to tune the interaction dynamics with the surrounding environment. By using these technologies on a robotic ’hand’ he has shown it possible to apply the appropriate ‘strain’ to secure and trim the lettuce without damage.

Visit to the Maxwell Centre for Interdisciplinary Engineering

The late afternoon was spent at the Maxwell Centre Dr Agnieszka Iwasiewicz-Wabnig FRSA, Director Partnership Development enthusiastically explained the history, purpose and future proposals for the centre under the title, “Strategy and Serendipity”. This title reflects that people with knowledge or capability probably don’t talk enough to those that have a “need”. The centre was created to enable research and industry to meet and discuss needs and opportunities. It was highlighted that the centre is not a “gatekeeper” but a signpost to opportunities for co-development with the university. The volumes of potential research ideas and development possibilities were quickly identified as exceeding capacity so two key themes have been selected:

- The Carbon Zero challenge

- Science in medicine

A “continuous community” is envisaged which will permit a constant refreshment of ideas and thinking. Whilst participants will be subject to confidentiality agreements, the opportunity to maximise the co-creation and use of knowledge and scarce assets is seen to be key to success. The shared resources are designed to enable small companies and enterprises to use equipment that they would not otherwise have access to or be able to justify the investment. Additionally, participants would have access to experienced operators who could maximise the benefits to be gained.

The new building was two-thirds funded by the UK Government Research Partnership Investment Fund; the £25M raised by the University has enabled a significant building for research and innovation across the Physical Sciences and Technology.

One of the five participating companies is the Henry Royce Institute exploring savings in energy transmission; additionally there are ten hot desks for associated companies and fifty industry researchers. Local industry knowledge is brought in from the Cambridge Clean Tech network and local start-up companies. This network targets the creation and exchange of ideas and helps address the emerging challenges facing these small companies.

Successful demonstrations of the size and scope of ideas which have been launched include:

- Solar powered splitting of water to generate hydrogen

- Solar off-grid water pumping

- Sustainable ammonia production

- Photo reforming of plastics

- Science input into the policy for “forever” products eg Teflon

Physical evidence of the successful implementation of this initiative can be seen in companies including:

- MediSMITH – sustainable manufacturing for the medical technologies

- WaterScope – a 3D printed microscope for studying water purity in the field

- Xampla – a replacement product for single use plastic

- BT – increased use of copper twin core cables for data storage

- Centre for Digital Built Britain and their Innovation Hub

The briefing closed with Dr Agnieszka Iwasiewicz-Wabnig describing the vision for the Innovation District of the University Western Science campus comprising the Cavendish III laboratories, future-industry R&D facilities and the Health Tech Enterprise zone. The comparison of the initiative to a pinball machine was very appropriate demonstrating that whilst, as a developer you may get bounced about, the good ideas will be kept in play for a long time.

Dinner at Imperial War Museum Duxford

The group headed to the Imperial War Museum, Duxford for dinner.

After dinner there was a speech by Professor Richard Prager, Head of the Department of Engineering. He talked about challenging boundaries. Those between disciplines being broken down by developments and collaboration of engineering with healthcare, architecture and synthetic biology, to name a few. He also spoke of the boundaries of access to higher education. The need for effective outreach so that Cambridge continues to admit the brightest students with the greatest potential. He concluded by thanking the Master and the Company for choosing to visit the Department.