Metamaterials like sneaker midsoles and car bumpers are engineered to carry the load or resist impact, but designing these products to perform as expected can be an error-prone process. Now, Berkeley engineers have developed an innovative design method that leverages artificial intelligence and additive manufacturing to ensure that optimum functionality and target behaviours are built into these specialised materials.

As reported in the latest issue of Nature Communications, researchers used machine learning to inversely design complex mechanical behaviours of a material and engineering product that can be printed by a desktop 3D printer. This new AI-based design approach could potentially lead to better-performing materials, greatly simplify the manufacturing process, and enable the development of materials with novel mechanical properties.

“Our machine learning-based design method enables the rapid creation of material with prescribed user-defined performance and target properties,” said principal investigator Xiaoyu “Rayne” Zheng, associate professor of materials science and engineering. “This approach makes it possible for any user to define the mechanical behaviours of their desired product, and then leave the rest [of the work] to AI and a 3D printer to output a product that behaves exactly as desired.”

Products like helmets, boxing gloves and vehicle bumpers are designed with stress-strain or force-displacement curves that enable them to resist force and impact. These curves record the material’s full deformation history when subjected to load and reveal all the information about their mechanical properties. But, according to Zheng, current design methods cover only a limited selection of mechanical properties, and the desired properties are rarely reflected in the measured values due to uncertainty and errors in the manufacturing process.

Given this challenge, the researchers set out to develop an AI-based approach to material design that would bypass the iterative design-manufacturing process while yielding a product with precise mechanical behaviours.

“With our method, a user can input a desired mechanical behaviour described by a curve, and this data is then fed into the machine learning code to generate a design — a process that takes only a few seconds. And once that design is 3D printed, it will replicate the desired mechanical behaviour,” said Zheng. “While still in its early stages, our machine learning-based design method can produce almost any type of material behaviour with nearly 90% accuracy.”

To create their AI-based design approach, the researchers first had to develop and implement an integrated machine learning framework, which consists of an inverse prediction module and a forward validation module.

“The inverse module uses the desired mechanical behaviours to design the micro-structure of the material, and the designed material is passed to the forward module for the evaluation of its mechanical behaviours,” said Chansoo Ha, co-lead author of this study and formerly a postdoctoral researcher at Virginia Tech in Zheng’s lab. “This helps ensure that the desired properties are accurately reflected in the finished product.”

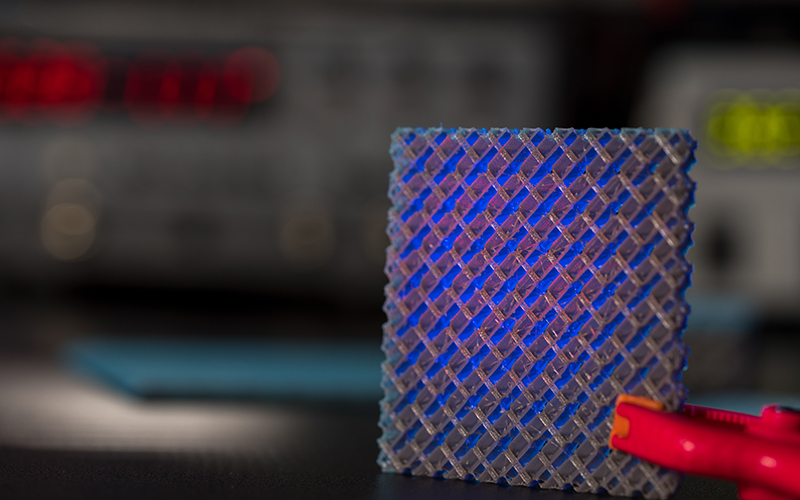

Next, they developed a family of cubic symmetric, strut-based cells to train the machine learning model. The cells’ lattice structure makes it possible to achieve almost any mechanical behaviour and the corresponding stress-strain curve. The researchers then 3D printed the cells and tested them to generate training datasets.

Using their new method, Zheng and his team fabricated a shoe midsole with the energy absorption and stiffness required by runners. They also demonstrated the potential for using machine learning to design structures, like car bumpers, that absorb a high amount of collision energy and minimise the amount of impact transmitted to the human body.

According to Zheng, protective gear, soundproofing material and more complex materials like optical film coatings — as well as those featuring band gap or shape memory effects — could also be good candidates for this design and fabrication method. Eventually, this approach may lead to the creation of materials with novel properties.

“Our AI-enabled design method generated mechanical behaviours that previously didn’t exist, such as materials that carry stress-strain curves containing advanced features, curvatures and shapes with tailored energy absorption,” said Zheng. “This discovery could provide a new paradigm for product and material design, one in which we are no longer limited to materials found in nature.”

In addition to Ha, the lead authors of this study include graduate researchers Desheng Yao and Zhenpeng Xu, both from Zheng’s lab. Co-authors include Chenang Liu, Oklahoma State University; Zhenyu Kong, Virginia Tech; Mathieu Bauchy, UCLA; and Vikram Deshpande, University of Cambridge. This work is funded partially by the Office of Naval Research and NSF Designing Materials to Revolutionise and Engineer our Future programme.