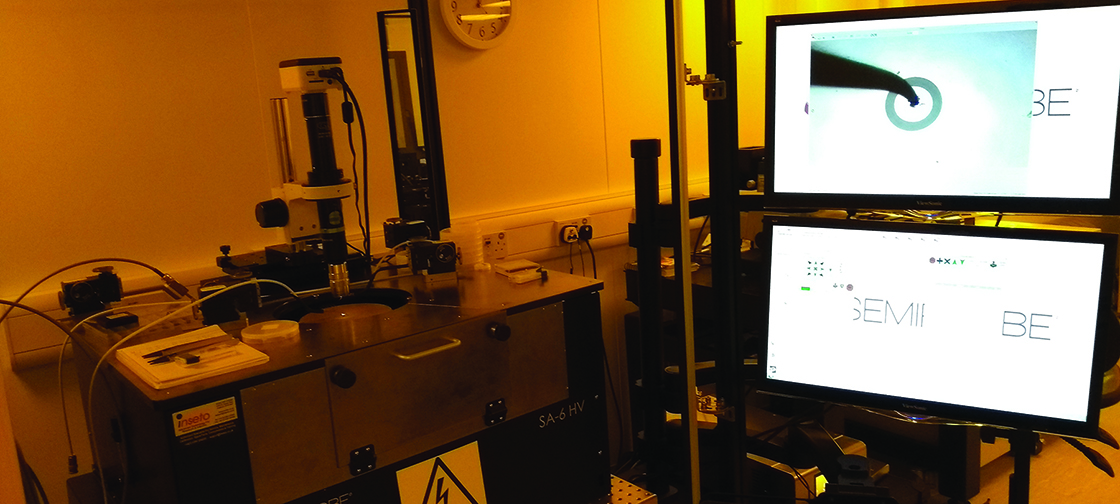

Inseto, a leading technical distributor of equipment and materials, has supplied the University of Warwick with a SemiProbe PS4L probe system for developing fabrication processes for next generation silicon-carbide (SiC) power semiconductor devices. The PS4L provides an accurate and repeatable means of mechanically interfacing fabricated prototype devices – as die or still on the wafer – with an analyser that can inject thousands of volts and measure hundreds of amps.

Dr Peter Gammon, Associate Professor (Reader) in SiC Power Electronics at the University of Warwick,

comments: “We’re involved in a number of projects that are pushing the boundaries of silicon carbide power

device research that will hopefully lead to the volume manufacture of device types that can currently only be

fabricated in silicon. The PS4L is an invaluable tool in our endeavours as not only can it handle the high power

from/to the analyser, but it is semi-automated, allowing us to collect a large amount of data from highly

repeatable tests.”

Dr Gammon goes on say that most commercially available SiC power devices are unipolar structures, such as

diodes and MOSFETs, which are well established and commercially available with high voltage ratings.

“We’re looking beyond these though, at bipolar devices that include IGBTs and thyristors because they will

further enable highly efficient and ultra-high voltage applications, such as traction inverters and high voltage

direct current in a low carbon society,” says Dr Gammon. “For example, silicon IGBTs are typically rated up to about 2,000V. As part of our work with the EPSRC Centre for Power Electronics, we are today producing silicon carbide IGBTs rated to 10,000V, with scope to go to 30,000V in the future.”

The PS4L is enabling Dr Gammon’s team to apply voltages of up to 10,000V and measure currents of up to

100A to confirm the performance and breakdown voltages of their devices. He says: “While we’re heading

towards the production of IGBT and MOSFET switches, we’re able to do much of our work on simple structures such as diodes, in order to evaluate the repeatability of our fabrication processes.”

Following the supply and commissioning of the SemiProbe equipment, a software interface was written by Dr

Gammon’s team to enable the PS4L and the high voltage parameter analyser to work together. “Both OEMs

were incredibly supportive and gave us access to the source code of their respective products,” notes Dr

Gammon.

The equipment is in use at the University of Warwick, one of only a few universities in the UK with SiC

fabrication capabilities, and it has already enabled Dr Gammon’s team to capture data from larger test batches than would have otherwise been practical before. Also, there is more confidence in the data collected through automated processing, as it removes the discrepancies of manually obtained data, such as probe tip to pad alignment inconsistences and variations in contact force.

Dr Gammon, concludes: “Our new equipment represents a real game changer and the support Inseto provided has been exemplary throughout the entire process, from them understanding our requirements through to ensuring the PS4L was fit for purpose now and in the future.”

Inseto is exclusive distributor for SemiProbe in UK, Ireland and Northern Europe