Canterbury Christ Church University recently played host to students from across the southeast, who gathered to be honoured for their groundbreaking engineering designs geared toward tackling real-world challenges.

The entire cohort had participated in the Primary Engineers Leaders Award, a nationwide competition that has now reached its tenth year and involved over 48,000 students across the UK. It tasks young minds aged 3 to 19 with the query: “If you were an engineer, what would you do?” Encouraging them to conjure imaginative remedies for issues they observe in their lives and the global landscape.

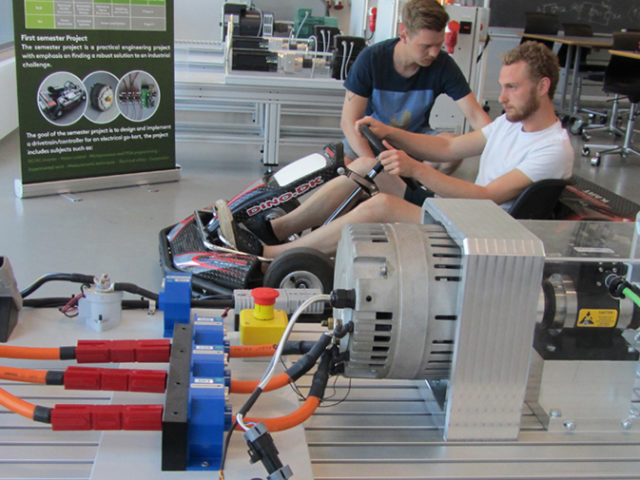

The contest serves a dual purpose – stoking a fascination for engineering and affording youngsters the chance to connect with local engineers, delving into their career trajectories and sources of inspiration. Participants are subsequently motivated to scrutinise their surroundings for problems susceptible to engineering solutions, which they then submit for the competition. Each entry undergoes evaluation by local engineers and scholars. The University, a vital regional collaborator, contributed to the evaluation process. Every submission garners a certificate and grade, with a subset progressing to clinch the victory.

Several of the victorious designs encompassed innovations like robots assisting the unwell, hair scrunchies equipped with emergency buttons for location alerts, and an automated bookshelf proficient at pinpointing desired books. In the words of Chris Rochester, UK Director of Primary Engineer, “For a decade we have been working with young people to inspire the next generation of engineers, with Canterbury Christ Church University as our southeast partner for five of those years.”

He went on to express admiration for the perennially impressive designs, lauding the extraordinary creativity and empathetic drive evident in these young problem-solvers.

Preston, in devising his creation, accounted not only for the discomfort of venturing out in the cold but also for potential accidents while clearing snow. His robot, equipped with a heated scoop, transfers snow to a reservoir for later use as water. This innovative solution contributes to water conservation. Additionally, the robot disperses rock salt on cleared paths to avert refreezing, incorporates a GPS sensor for precise area identification, features Bluetooth for remote control, and boasts rechargeable batteries and solar charging options.

Preston illuminated his process, sharing, “I had a concept for the design even before I entered the competition, but the process of refining it for the competition was enjoyable. Winning isn’t something I often experience, so this achievement is quite fulfilling. I aspire to be an engineer and inventor, driven by a desire to enhance our world.”

Dr. Anne Nortcliffe, Head of the University’s School of Engineering, Technology, and Design, commended this year’s talented young designers, highlighting the unconstrained problem-solving prowess of children and the valuable lessons adults can glean from them. Collaborating with Primary Engineer, she noted the gratification in witnessing these innovative designs come to life.

The awards ceremony also unveiled two prototypes from the previous year’s winners.

The first prototype, conceived by Alice (Year 3) from Arunside School, was crafted by Breeshea Robinson, Senior Specialist Technician at the University’s School of Engineering, Technology, and Design. Alice’s “Magic Cover” innovation aimed to provide children with an easily usable earring cover, eliminating the need to tape over jewellery during physical activities. Breeshea realised the prototype using 3D printers, heralding a tidier and more protective solution.

In the words of Breeshea, “It’s a brilliant design that addresses a common issue among young people in school. I recall the tape-on-ear approach, and this alternative promises greater neatness and enhanced protection.”

The second prototype, “Face for a Plant,” was conceived by Zavier (Year 3), also from Arunside School. Manufactured by Thales, Zavier’s creation endeavours to transform plant health monitoring. Sensors around the plant gauge conditions like light, temperature, humidity, and soil moisture. Data is processed and conveyed through a screen integrated into the pot, displaying emotions such as happiness, sadness, and thirst.

In Zavier’s succinct assessment, the prototype perfectly embodied his vision.