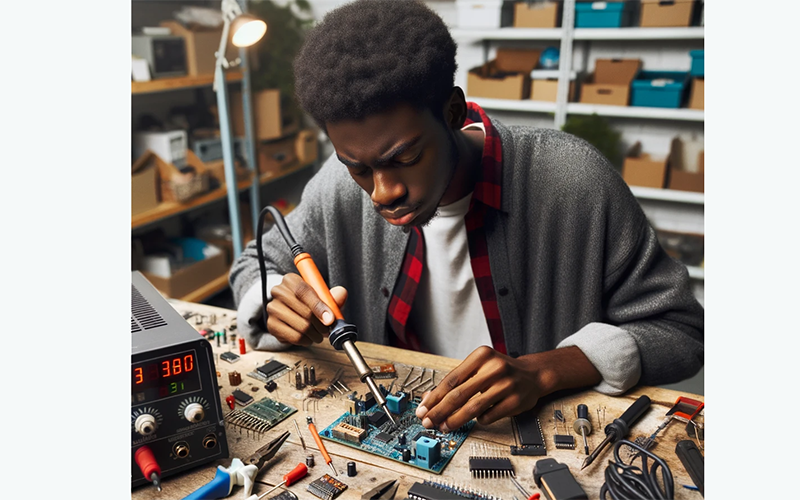

Soldering, a fundamental skill in the electronics industry, involves the use of a soldering iron to melt solder, thereby creating a strong electrical connection between components.

For those new to the craft, mastering the basics is essential to ensure safe, efficient, and reliable soldering.

This article outlines some fundamental techniques and best practices to help beginners get started.

Safety first

Before commencing any soldering task, it is paramount to ensure a safe working environment. Always wear safety glasses to protect the eyes from stray solder or flux splatters. Work in a well-ventilated area to avoid the inhalation of fumes and keep a fire extinguisher close by.

Selecting the right tools

Choosing the right soldering iron and solder is crucial. For most electronics work, a soldering iron with a power rating of 20-40 watts suffices. The solder used should be rosin-core solder, which has a built-in flux to aid the soldering process.

Preparing the soldering iron

Once the soldering iron reaches its optimal temperature, clean the tip using a damp sponge. A clean tip ensures better heat transfer and a more efficient soldering process.

Tinning the tip

After cleaning, apply a small amount of solder to the tip of the iron. This process, known as tinning, helps improve heat transfer from the iron to the components.

Soldering the components

Hold the soldering iron like a pen and bring the tip in contact with the component lead and the pad on the circuit board. After a few seconds, introduce the solder wire to the joint. Once the solder melts and flows around the joint, remove the solder, followed by the iron.

Inspecting the joint

A well-soldered joint will appear shiny and have a concave shape. If it looks dull or forms a blob, it may be a cold joint, which can result in a poor electrical connection. In such cases, it’s advisable to re-solder the joint.

Cooling and cleaning

Allow the joint to cool naturally. Avoid blowing on it, as rapid cooling can lead to a brittle joint. Once cooled, clean the joint with isopropyl alcohol to remove any residual flux.

Soldering is a skill that requires practice and patience. With the right tools and techniques, even beginners can achieve consistent and reliable soldered joints. As always, safety should remain a top priority, and it is advisable to seek guidance or training from experienced professionals when starting out.