In the space of just six weeks, five young engineers on an innovative academy programme have designed a Submersible Remotely Operated Vehicle (SROV) to safely clean biofouling from submarines and shipping vessels.

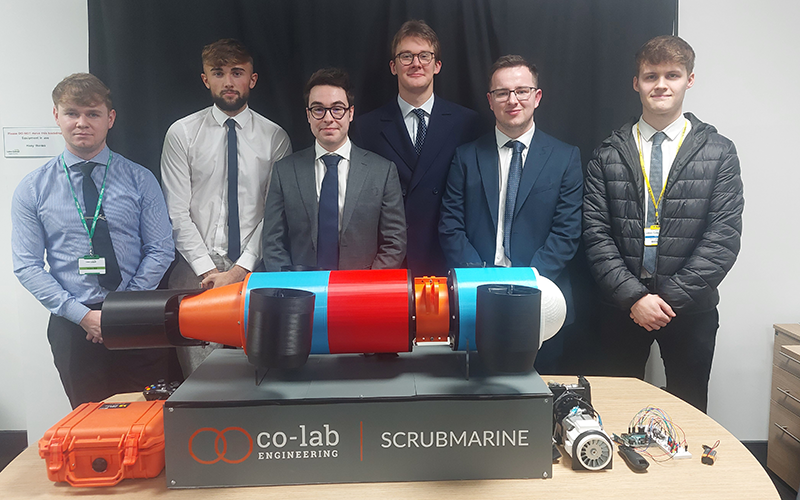

The first cohort of the newly launched Co-Lab Engineering Academy, which brings together engineers to work collaboratively to solve a real-life industry challenge, presented a concept design of their ScrubMarine innovation at an event to conclude a successful debut programme.

Mentored throughout the project by Co-Lab Engineering Managing Director Clyne Albertelli, the delegates learned technical, leadership and project skills, which will prove invaluable when they return to their places of work.

Picking up a challenge to find a method of cleaning unwanted biofouling from the hulls of submarines and ships from the Defense and Security Accelerator (DASA), on behalf of the Royal Navy, the team produced an SROV which will include specialist cleaning nozzles that induce cavitation to remove the biofouling, controlled from a remote distance.

This will limit the need for divers to carry out cleaning work. Still, other benefits of the innovation include: reduced cleaning costs, easier deployment, longer operational times, and the machine will be available more frequently than existing methods.

Dylan Brennan, a nuclear graduate working with Jacobs, was appointed as the project’s team leader and was amazed at how much the team of engineers progressed in such a short time.

He said: “I was skeptical at first that we could pull off such an ambitious project within the timeframe, but the way that five strangers were pulled together and given the guidance required to produce something has been amazing, and we’re all incredibly proud of what we have achieved.

“Usually, on a project, you don’t tend to see the finished article, but we all worked on every aspect of the project, and this has given me a greater appreciation of what each department does and how we can tailor what work we do to make sure everything is right throughout the whole process.”

Thomas Clayton, a mechanical design degree apprentice at Sellafield, was the mechanical lead on the project.

He said: “This has been a really good opportunity to develop the skills of engineers like myself who are early into their careers, and it gave us all the opportunity to take ownership of an entire project, from start to finish.

“It has been an enjoyable experience and one I would recommend to all engineers, whether just starting out in their careers or even with decades of experience in industry, because the mentoring, hands-on approach and freedom to experiment has been so valuable to adapt into our line of work.”

Co-Lab Engineering founder Clyne, a former Solutions Manager for Sellafield, introduced the Engineering Academy to challenge engineers to work collaboratively to find a rapid solution to a live problem within a six-week, ‘sprint’ period, from identifying the challenge, designing a model and then developing a prototype to present to the challenge owner.

He has been impressed with the teamwork and camaraderie among the first group – and particularly with the ScrubMarine SROV produced at the end of the six weeks.

Clyne said: “The whole ethos of Co-Lab Engineering centres around collaboration and pooling together resources for a mutual benefit, and the Engineering Academy was borne out of a desire to develop the capabilities of engineers to benefit industry for years to come.

“I couldn’t be more proud of the development and progress made by all members of the team during the Academy project and we are excited about how we can develop the programme further to continue improving skills across all industries.”

Co-Lab Engineering Academy is preparing for its second project which will challenge participants to develop world-first technology to convert water supplies into electricity within domestic and community settings.

Teaming up with Technology Consortia Limited Cumbria, the creation of Compact Hydro Energy Devices is aimed at making power generation across the UK more sustainable.

The next Academy programme will begin on January 16, with further projects planned throughout 2023.

The Engineering Academy is being supported by delivery partners the Institution of Mechanical Engineers (IMechE), University of Cumbria, the Centre for Leadership Performance and TEDx speaker Jo Corbishley, who will all feature in the activities during the six-week programme.