Lam Research Tech Symposium, co-hosted by MIT.nano and Microsystems Technology Lab, explores challenges, opportunities for the future of the industry.

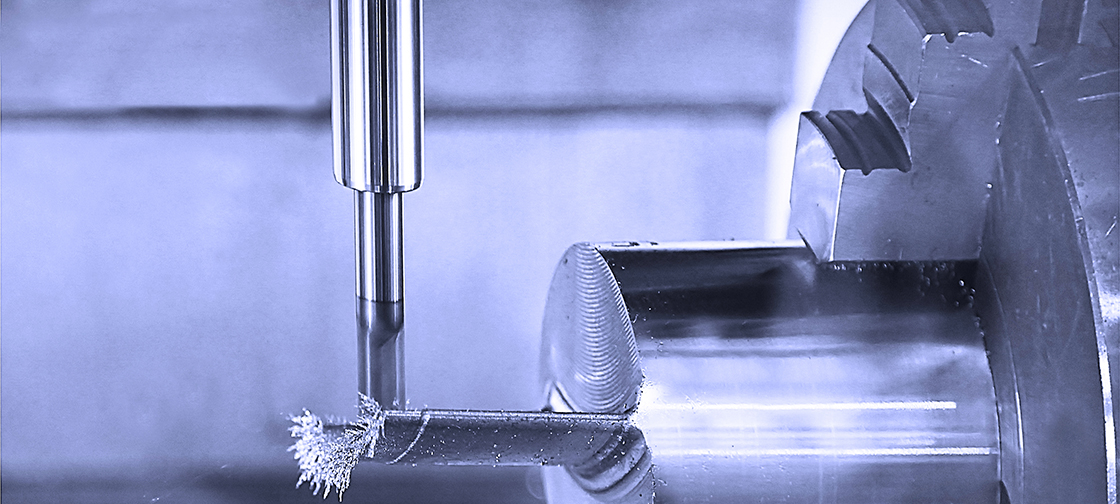

Integrating smart systems into manufacturing offers the potential to transform many industries. Lam Research, a founding member of the MIT.nano Consortium and a longtime member of the Microsystems Technology Lab (MTL) Microsystems Industrial Group, explored the challenges and opportunities smart systems bring to the semiconductor industry at its annual technical symposium, held at MIT in October.

Co-hosted by MIT.nano and the MTL, the two-day event brought together Lam’s global technical staff, academic collaborators, and industry leaders with MIT faculty, students, and researchers to focus on software and hardware needed for smart manufacturing and process controls.

Tim Archer, president and CEO of Lam Research, kicked off the first day, noting that “the semiconductor industry is more impactful to people’s lives than ever before.”

“We stand at an innovation inflection point where smart systems will transform the way we work and live,” says Rick Gottscho, executive vice president and chief technology officer of Lam Research. “The event inspires us to make the impossible possible, through learning about exciting research opportunities that drive innovation, fostering collaboration between industry and academia to discover best-in-class solutions together, and engaging researchers and students in our industry. For all of us to realize the opportunities of smart systems, we have to embrace challenges, disrupt conventions, and collaborate.”

The symposium featured speakers from MIT and Lam Research, as well as the University of California at Berkeley, Tsinghua University in Beijing, Stanford University, Winbond Electronics Corporation, Harting Technology Group, and GlobalFoundries, among others. Professors, corporate leaders, and MIT students came together over discussions of machine learning, micro- and nanofabrication, big data — and how it all relates to the semiconductor industry.

Source: “Smart systems for semiconductor manufacturing”, Amanda Stoll, MIT.nano, MIT News