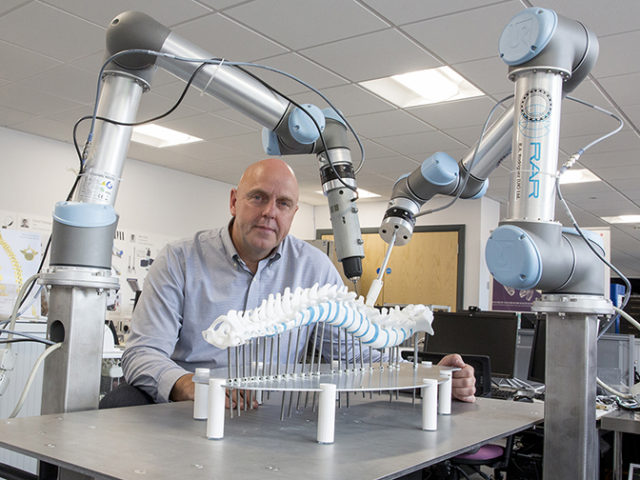

Developed in close cooperation with all the participating institutes, the Virtual Lab will digitally link all areas and institutes in the field of metallic additive manufacturing (metal AM) via a network and a database. Thus, it plays an important role in the Fraunhofer lighthouse project.

At formnext, the Fraunhofer experts will demonstrate what this lab can do and how it will work. Fritz Lange from the Fraunhofer Research Institution for Additive Manufacturing Technologies IAPT in Hamburg, where the threads of the virtual laboratory converge, explains, “The institutes will use the Virtual Lab to process and track distributed manufacturing.” They also plan to create a closed digital representation of the competencies and equipment of all participating institutes.

Integrated and virtual

The Virtual Lab makes the entire AM process transparent and reflects it digitally: Digital Twins enable project participants to model and simulate processes in order to optimize real systems in all areas of industrial manufacturing. The Virtual Lab is ready for operation and is already being evaluated with so-called dummy data. Currently, the participating institutes are connecting to the Virtual Lab via their database so that the lab can soon start its virtual operation.

Among these institutes is, for example, the Fraunhofer Institute for Material and Beam Technology IWS in Dresden, being responsible for developing the materials in the project. The institute will focus on expanding the range of materials that can be processed by means of additive manufacturing and also on multi-material constructions: Here, laser material deposition (LMD) is used to tailor a component from various materials without needing downstream joining processes. “The process accelerates material development enormously,” says IWS scientist Michael Müller.

Source: “Fraunhofer lighthouse project futureAM at formnext: Metal AM on the verge of breakthrough”, Fraunhofer Institute of Laser Technology ILT